PRESS RELEASE: HOVMAND LAUNCHES NEW FLEXIBLE LIFITING EQUIPMENT

Køge, 8 January 2020 +++ New items in the Hovmand lifting equipment range include a flexible system for forks and booms, a rotating fork and an adaptable crane arm system. This significantly extends the potential applications of the company’s mobile lifting and transport solutions for efficient and safe material handling.

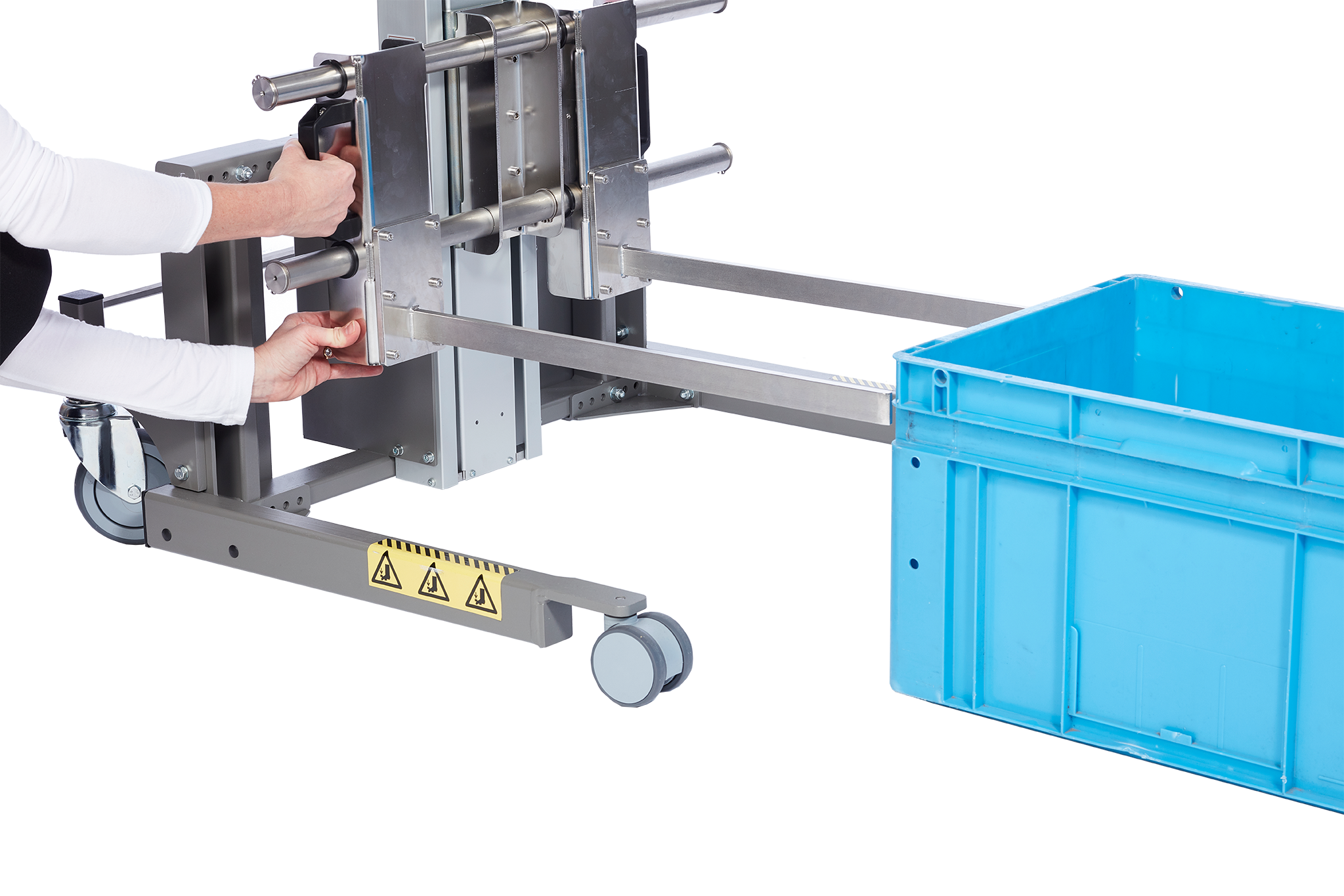

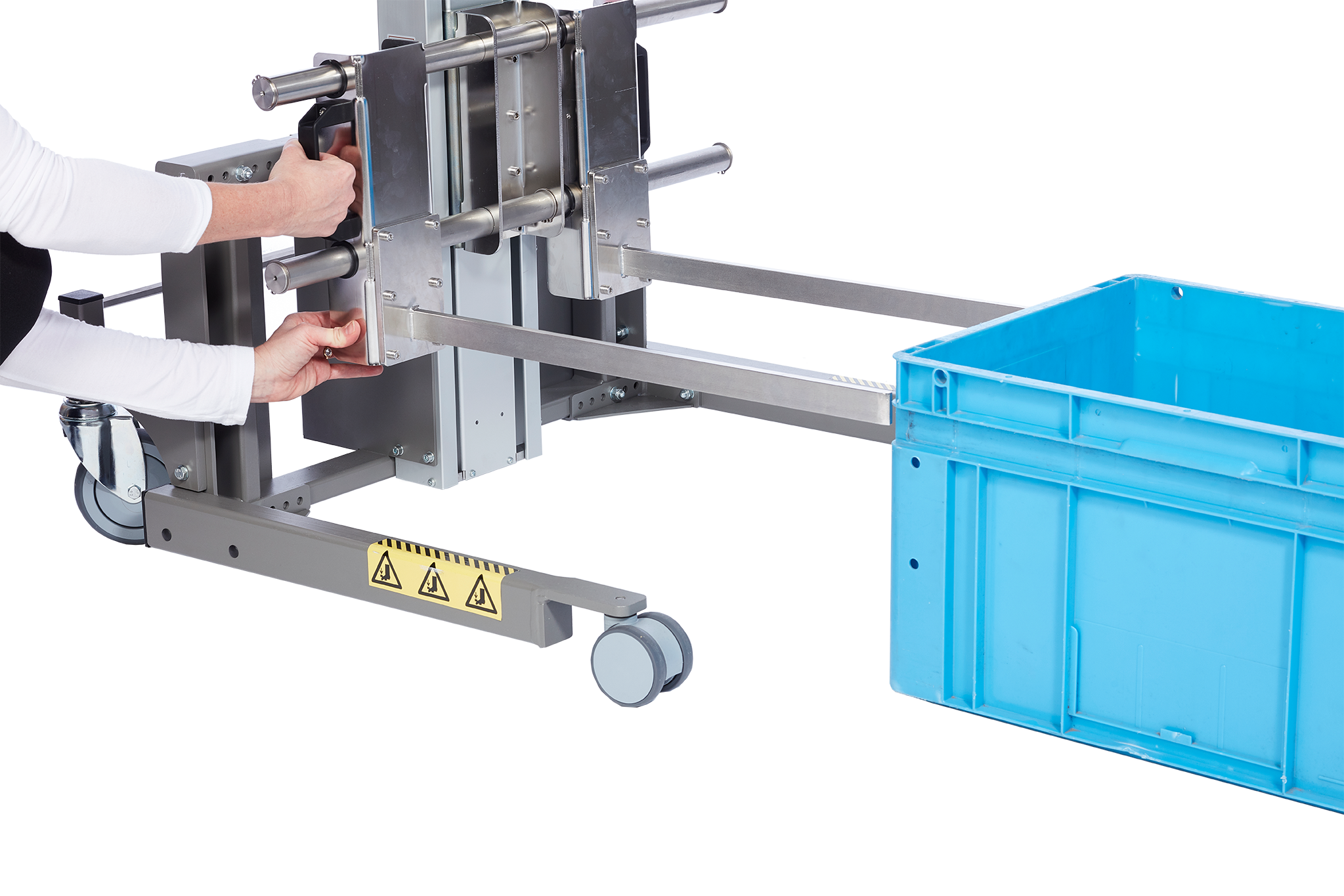

Forks can be used to lift, transport and stack crates in the production process – even in the most confined of spaces. With its underlying carriage construction, the new Flex Fork can be easily and conveniently adjusted to different crate widths by the customer – even during use.

This means that not only standard crates can be moved effortlessly but also wider or narrower ones. The Flex Double Boom is used for handling reels by lifting them from the bottom. Here too, customers themselves can easily adjust the width to different reel sizes.

Normally, handling different crate widths and reel sizes requires investment in an additional device. But these additional costs are eliminated for the customer thanks to the variable adjustment options provided by the Flex Fork and Flex Double Boom.

Another innovation, the rotating fork, is equipped with a manually operated rotating unit for tilting and tipping crates. This rotating unit can be used to set the tilt angle to 30 or 90 degrees. The creates can therefore be set in an optimum working position and emptied much more easily, avoiding strenuous turning and bending of the upper abdomen.

Another new item in the Hovmand range is a flexibly configurable crane arm solution: equipped with an electric lifter and a cross-bar with belts for picking up loads, it enables heavy, bulky sacks or other items – made of metal, for example – to be transported conveniently and ergonomically

The cross-bar stabilises the material by means of at least two pick-up points, thereby preventing the load from swinging back and forth. All new lifting equipment items are suitable both for the industrial lifters of the INOX line made of stainless steel, designed for environments with special hygiene requirements, and for the IMPACT series made of aluminium for use in production, warehouse and logistics environments.

MODULAR CONFIGURATION OPTIONS

Hovmand – the world's leading manufacturer of mobile battery-powered industrial lifters – has set itself the goal of increasing the modular options available for its lifters. This often eliminates the need for time-consuming and cost-intensive customisation so as to meet specific customer challenges in material handling.

“Thanks to our modular products we are able to offer a much wider range of lifter configurations for occupational health and safety that are individually tailored to the respective requirements. This gives our customers more flexible and cost-effective solutions in series production,” says managing director Søren Hovmand.

LIFTER CONFIGURATION WITH AR TECHNOLOGY

The Hovmand Virtual Engineering App supports individual selection of needs-based lifting solutions. Using the app, Hovmand Sales is able to put together the right solution for the customer from over 100,000 configuration options on site at the customer's premises and present it live in 3D thanks to augmented reality technology.

This on-site selection and presentation gives decision-makers an accurate impression of the industrial lifter and the benefits it offers in terms of process optimisation and occupational safety. The virtual representation of the lifter in its surroundings can be saved as a photo and forwarded to those involved in the decision-making process.

“This greatly simplifies and speeds up the planning and decision-making process for our customers,” says Søren Hovmand.