How to Handle a Plastic Box?

Many logistics systems use stacking boxes of different types as an integrated part of merchandise management. With a fork tool, numerous plastic boxes can be handled easily and efficiently. The fork tool is utilized in combination with boxes that feature an edge around their top surface or grooves along their sides, creating space for the instrument to get ahold. Whether you are looking to lift a single plastic box or stack several boxes, the tool gets the job done. By placing the fork prongs around the box, the edges and grooves work to your advantage and enable a tight grip, for secure handling.

We offer different types of forks in our assortment of tools, all fitting with a wide selection of boxes. For example, our G1 fork is a safe choice due to its versatile application and perfect compatibility with nearly all standard box sizes. You can see it in live-action in our first video above.

If you handle boxes with unique measurements, we have fork tools that offer the possibility for width adaptation. This type of tool is also well-suited for moving and lifting boxes of various sizes. See for yourself in the second video above.

Finally, if you are looking to empty boxes, our forks can be combined with a turning unit which ensures the entire process becomes seamless, as evident in our third video.

Is it Possible to Lift a KLT Box?

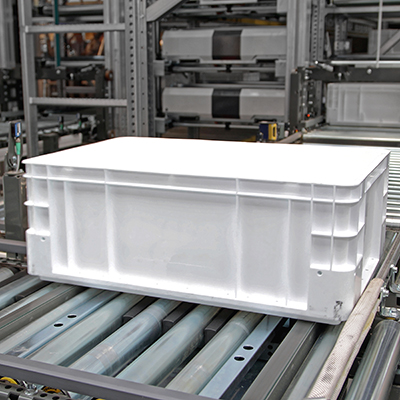

A number of boxes do not have rims or grooves surrounding their surfaces, complicating compatibility with lifting solutions. Particularly, this type of box is prominent within internal logistics, where many processes are automated, and boxes are moved around by means of assembly lines. However, boxes still have to be moved and lifted beyond the automated processes and this often creates unforeseen challenges that put employees at risk of permanent discomfort, accidents and musculoskeletal disorders.

To overcome the challenge, we have created our KLT-fork with prongs that slide into the depressions, on the side of the box. The lifting device tightly grips hold of the box, ensuring safe handling without putting a strain on workers’ health. You can see the innovative tool’s application in the first video above.

Handling Cardboard and Other Odd Size Boxes

Boxes come in a myriad of sizes and many different materials. Some are designed to be easy to grip and lift, while others pose as more challenging to move, tilt and empty. Moreover, boxes can be made from cardboard, have rims and grooves or feature handles. Sometimes many different sizes and types are even processed in the same workflow, setting additional requirements for the lifting tools which aid in handling the boxes and maintaining employee health.

Luckily, Hovmand is a specialist in the field of material handling, offering solutions equipped to overcome nearly all challenges. For example, boxes that cannot be lifted with a fork tool can be handled with a platform. Powered by a remote control unit, the platform is easily positioned at the right height, enabling boxes to be pushed from positions such as shelves, and onto the platform or vice versa.

Our platforms are offered in different materials, including aluminum, stainless steel, plastic (approved for the food industry) and wood. Also, they are available in sizes up to 600x600 mm (~24x24 in.) and if needed, we can even provide them on a larger scale.

If the box is large or heavy, the platform can be mounted with rollers in front and/or on the side so loading and unloading becomes easy.

Ergonomic ways to handle and lift crates and boxes

Handle stacking boxes of various sizes with flex fork

Lift and empty boxes without physical exertion: Turnable Fork