Bring ergonomics and efficiency into your production line

In the continuously growing and rapidly evolving electronics industry, a vast number of parts are moved throughout the supply chain on a daily basis. Hereunder, the parts are of multiple sizes, weight classes, and temperatures, making their lifting repetitive and complicated in nature.

Hovmand offers a large number of ESD-equipped and versatile lifting solutions that operate as your perfect lifting aid in the industry’s sensitive environment.

Continue reading to learn more about the challenges specific to the electronics industries, and how we can help you minimise physical strain and maximise efficiency.

Transporting servers safely and efficiently

The need for data centres is increasing on a global scale and, therefore, so are the challenges associated with their daily operations. To comply with these environments’ strict requirements Hovmand has developed a number of ESD-equipped lifters and tools.

Hovmand’s lifting solutions provide maximum safety and ease transport of heavy servers from racks and throughout data centres or server rooms. With a carefully designed platform with rollers, handling becomes an effortless task.

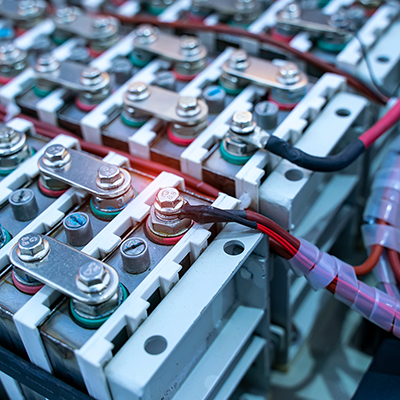

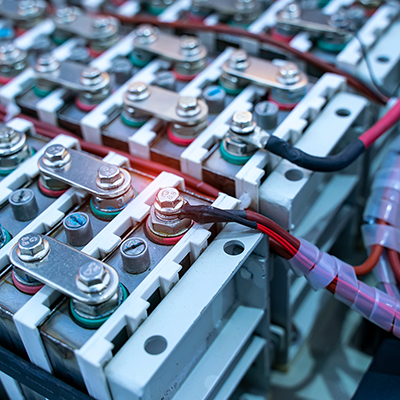

Handling batteries without physical strain

The technological advancement within batteries has fostered a vibrantly growing market with continued integration in more and more production lines. However, batteries often require storage and charging in specialized cabinets as well as transportation to and from test stations.

Hovmand’s lifters are carefully designed to comply with the strict requirements in electronic heavy environments. With one or more of our lifting solutions, you can remove the physical strain on workers through more precise handling and simultaneously ensure increased productivity.

Custom solutions

Many companies rely on custom electronic components throughout their production. However, such components often entail special measurements that don’t comply with standard lifting solutions, rendering them obsolete.

Thanks to our modular product architecture, we can quickly build a lifting solution according to your personalized requirements – while retaining cost-effectiveness. And no matter how you configure your next lifter, you are ensured to experience increased safety, efficiency and flexibility from day one.

Lifters for data centers and server rooms

Solutions for more productivity: Platforms in various materials

Online video product consultancy. Your lifting solutions in 3D